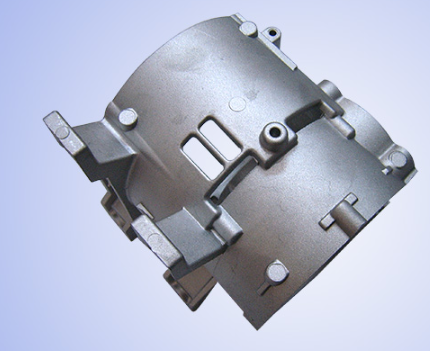

When die casting, it is equivalent to giving a continuous pressure to the metal liquid during the process of metal cooling, so that the metal liquid shrinks when it solidifies, but it will constantly be pressurized, so that the uncertainties generated when the product is cooled are densely covered with pressure, and finally achieve stable and high-precision casting.