What steps do you need to pay attention to in the design and manufacture of hardware die casting molds?

Release time:2023-11-23

What steps do you need to pay attention to in the design and manufacture of hardware die casting molds?

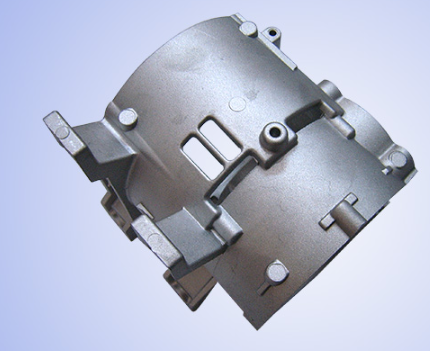

Hardware die casting mold is a tool for manufacturing hardware die casting parts, its design and manufacturing process needs to go through several steps. The following will introduce the design and manufacturing process of hardware die casting mold.

First, die casting mold design

1. Determine product requirements: First of all, you need to determine the requirements of the product to be manufactured, including size, shape, material, etc. These requirements will determine the design and manufacture of die casting molds.

2. Design die casting mold structure: According to product requirements, design mold structure, including mold cavity, cooling system, exhaust system, etc. The design of the mold structure needs to take into account the production efficiency, quality and cost of the product.

3. Determine the die casting mold material: select the appropriate mold material according to the product requirements and mold structure design. Die-casting mold materials need to have the characteristics of high strength, high hardness, high wear resistance and high corrosion resistance.

4. Develop die casting mold processing technology: According to die casting mold structure design and die casting mold material selection, develop die casting mold processing technology, including processing tools, processing sequence, processing parameters, etc.

5. Perform die casting mold analysis: Analyze the designed die casting mold, including the strength, stiffness, thermal deformation and other aspects of the die casting mold to ensure the quality and performance of the die casting mold.

Second, die casting mold manufacturing

1. Manufacture die casting mold parts: According to die casting mold design and processing technology, manufacture die casting mold parts, including mold base plate, cavity, cooling system, exhaust system, etc.

2. Assemble the die casting mold: assemble the parts of the manufactured die casting mold, including assembling the cavity, cooling system, exhaust system, etc., and carry out debugging and testing.

3. Debug the die casting mold: debug the assembled die casting mold, including adjusting the size, shape, cooling system, exhaust system, etc., to ensure the quality and performance of the die casting mold.

4. Perform die casting mold testing: test the debugs of the die casting mold, including die casting mold testing, trial production and other tests to ensure the production efficiency, quality and cost of the die casting mold.

5. Maintenance of die casting mold: maintenance of the used die casting mold, including cleaning, lubrication, repair, etc., to extend the service life of the die casting mold and ensure the quality and performance of the mold.

In short, the design and manufacturing of hardware die casting molds need to go through a number of steps, including determining product requirements, designing die casting mold structure, determining die casting mold materials, developing die casting mold processing technology, die-casting mold analysis, manufacturing die casting mold parts, die-casting mold assembly, die-casting mold debugging, die-casting mold testing and die-casting mold maintenance. Only after a strict design and manufacturing process, can we produce hardware die-casting molds with excellent quality and performance.