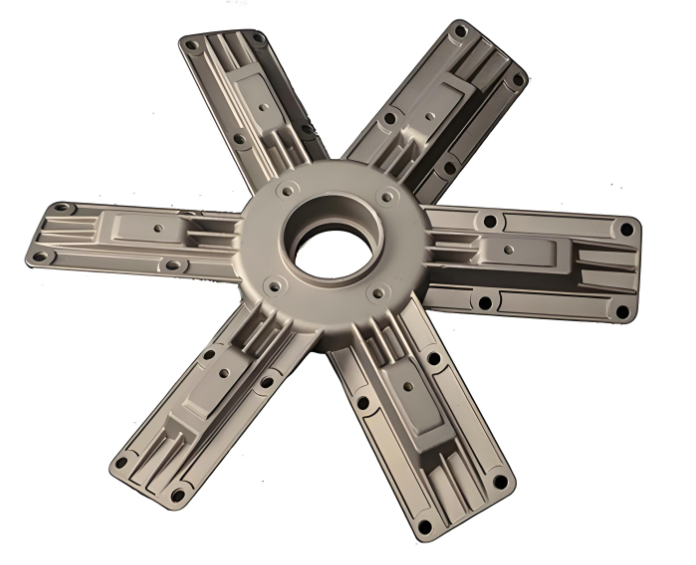

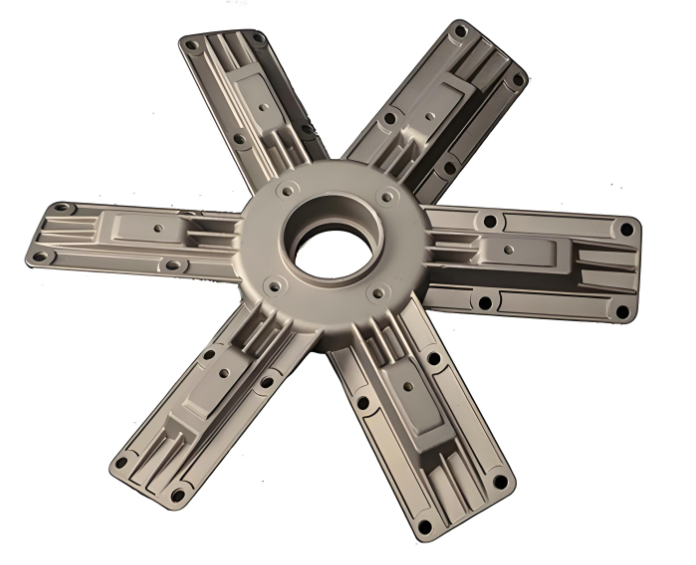

What are the zinc alloy die casting processes?

Release time:2024-05-15

What are the zinc alloy die casting processes?

First, material preparation: First of all, you need to choose the appropriate zinc alloy material. The choice of these materials will directly affect the quality, performance and cost of the final product. These materials are then heated to their melting point to melt them into a liquid state for subsequent die casting operations.

Die preparation: The design and manufacture of the die is a key step in the zinc alloy die casting process. The shape and size of the mold need to precisely match the shape and size of the desired part. In addition, the mold also needs to be able to withstand high temperature and pressure environment, usually made of high temperature resistant materials. The manufacturing of mold includes a series of steps such as drawing review, material preparation, processing, mold frame processing, mold core processing, electrode processing, mold parts processing, inspection, assembly, flying mold, test mold and so on.

Third, die casting: after the mold is ready and preheated to the appropriate temperature, the liquid zinc alloy is injected into the mold. A high pressure is applied through a die casting machine to fill the cavity of the die with zinc alloy. This process requires control of injection speed and pressure to ensure that the molten metal is fully filled in the mold and obtained the desired shape and size.

Fourth, cooling and curing: After the die casting is completed, the parts need to be cooled in the mold for a period of time so that the zinc alloy can be fully solidified and cured. In this process, the cooling rate and temperature distribution need to be controlled to ensure that the solidification process of the parts is stable and uniform.

5. Demoulding: When the zinc alloy is completely solidified and cooled, open the mold and take out the molded product. At this time, the product may also need to undergo further finishing and processing.

Post-treatment: The removed zinc alloy parts need to undergo a series of post-treatment, including deburring, grinding, polishing, etc., to improve the surface quality and accuracy of the product.

Quality inspection: Finally, strict inspection and quality control of die-cast parts to ensure that products meet the specified standards and requirements. This includes checking aspects such as the size, appearance and performance of the parts.

This is the detailed process of zinc alloy die casting, each step is very important and needs to be strictly controlled to ensure the quality of the final product.