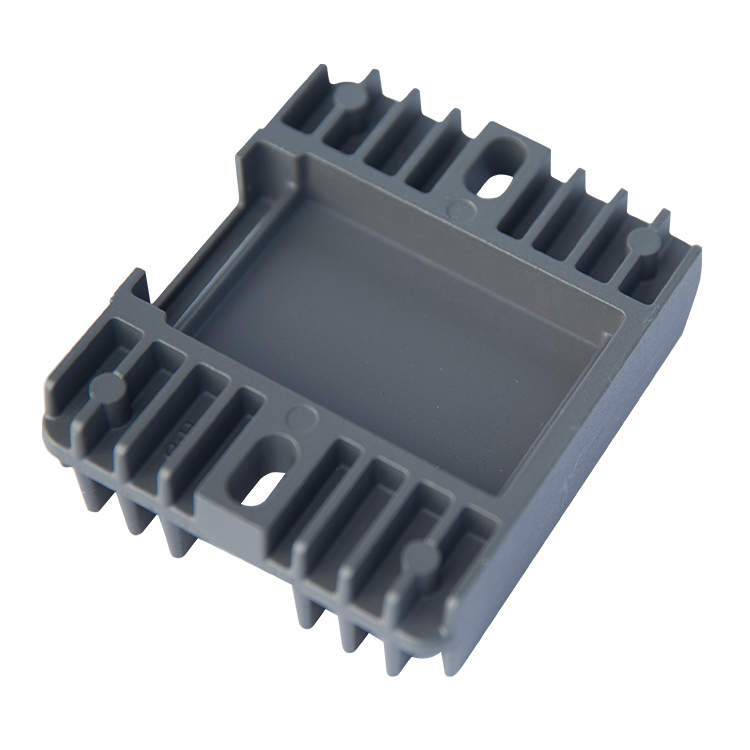

Compared with castings and forgings, stamping parts are thin, uniform, light and strong. Stamping can make the workpiece with rib, undulation or flanging which is difficult to be made by other methods, so as to improve its rigidity. Due to the use of precision die, the precision of workpiece can reach micron level, and the repetition precision is high, the specification is consistent, and the hole and socket, boss, etc. can be punched. Generally, cold stamping parts are no longer machined, or only need a small amount of machining. The accuracy and surface state of hot stamping parts are lower than that of cold stamping parts, but they are still better than castings and forgings, and the machining amount is less.