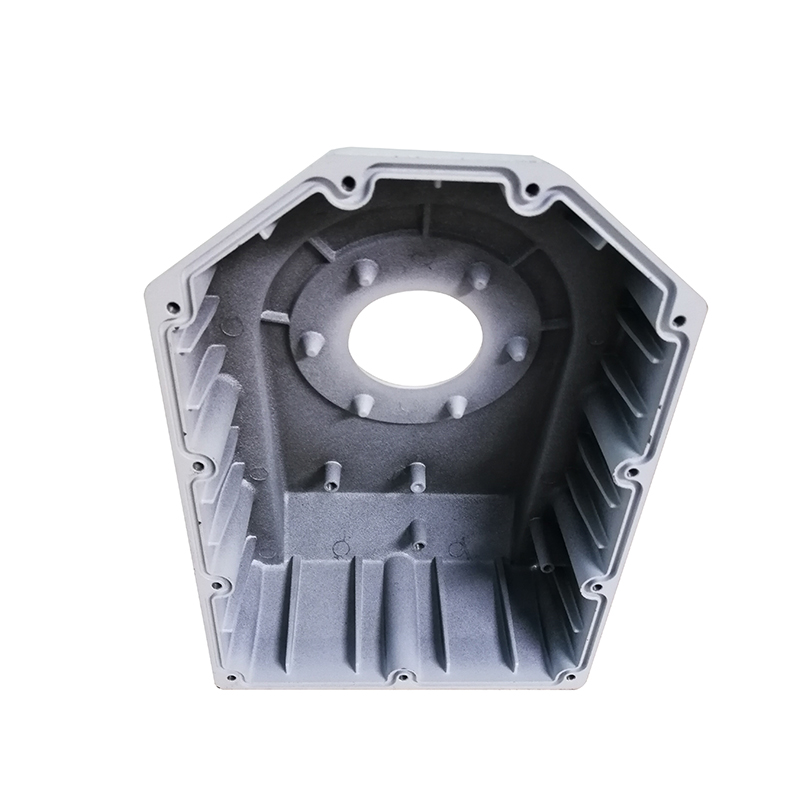

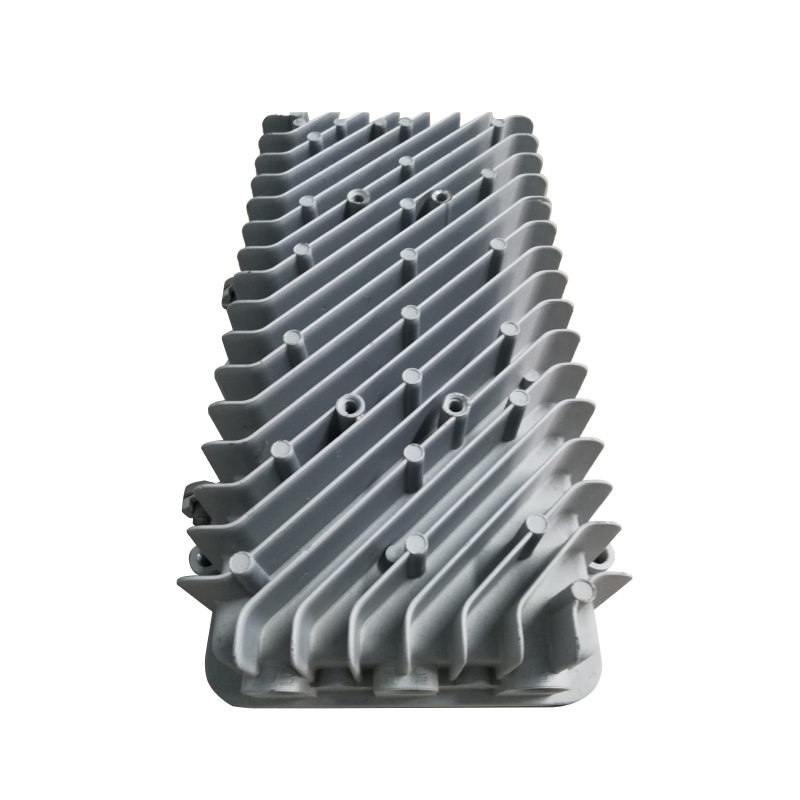

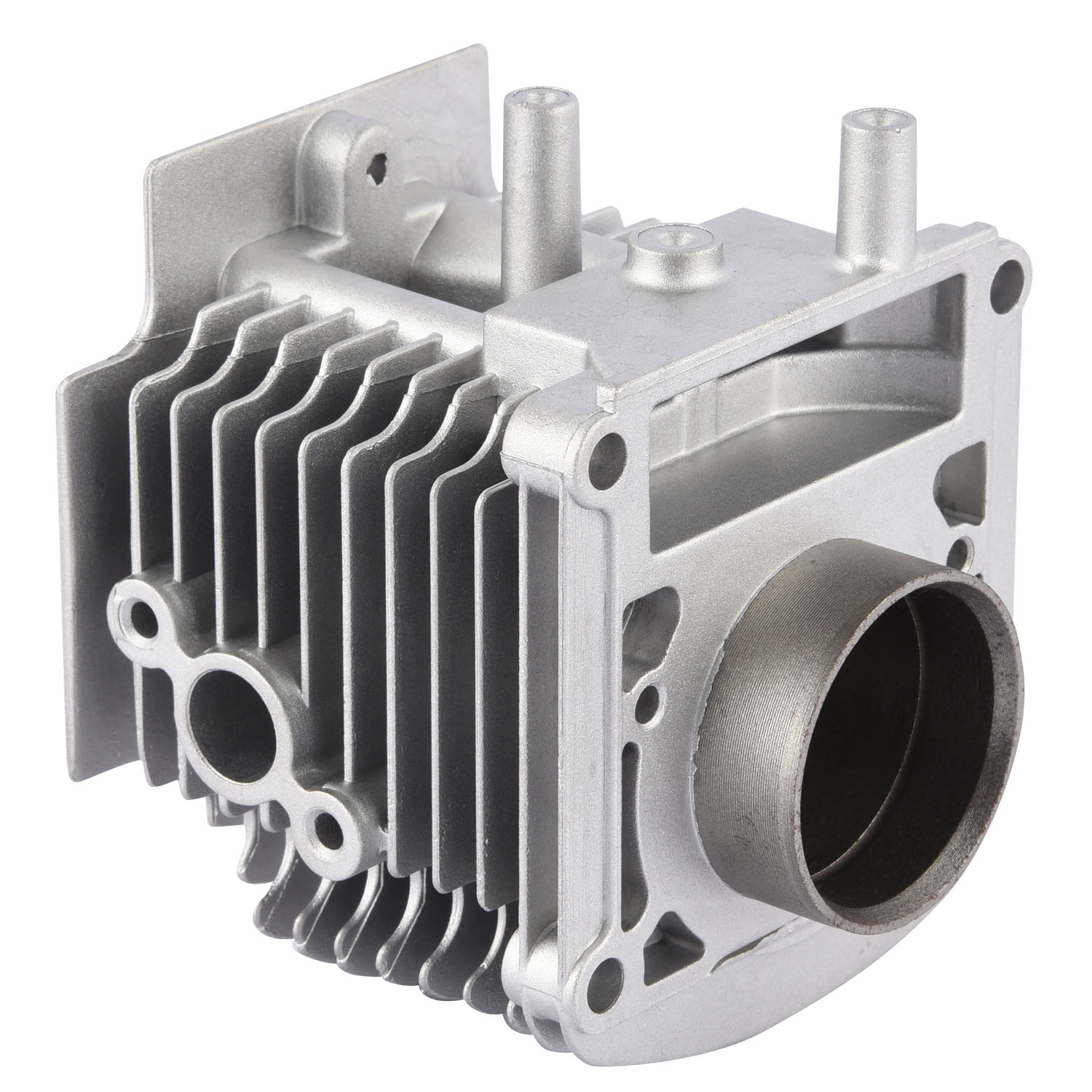

Die Cast Part is a kind of pressure casting part. It is a pressure-casting mechanical die-casting machine with a casting mold. The metal such as copper, zinc, aluminum or aluminum alloy heated to liquid is poured into the inlet of the die-casting machine. Die casting, casting copper, zinc, aluminum parts or aluminum alloy parts of the shape and size of the mold, such parts are often called die castings. Die-casting parts have different names in different places, such as die-cast parts, pressure castings, die-casting parts, die-casting aluminum, die-casting zinc parts, die-casting copper parts, zinc die-casting parts, Magnesium Die Casting Parts, aluminum die-casting parts, aluminum die-casting parts, aluminum Pressed alloy castings, aluminum alloy die-cast parts, etc.