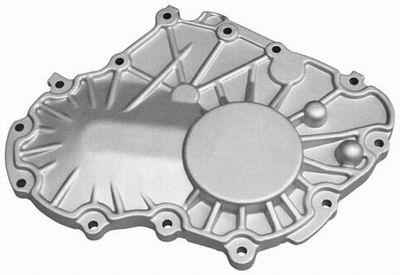

As a Die Casting Parts Supplier, share with you. Hot chamber die casting Hot chamber die casting, sometimes called gooseneck die casting, is a molten, liquid, semi-liquid metal in a metal pool that fills the mold under pressure. At the beginning of the cycle, the piston of the machine is in a contracted state, at which time the molten metal will fill the gooseneck. A pneumatic or hydraulic piston squeezes the metal and fills it into the mold. The advantages of this system include rapid cycling (approximately 15 cycles per minute), ease of automation, and the ability to melt metals. Disadvantages include the inability to die-cast metals with higher melting points, and die-casting of aluminum because aluminum will carry iron out of the molten pool. Therefore, hot chamber die casting machines are commonly used for zinc, tin and lead alloys.