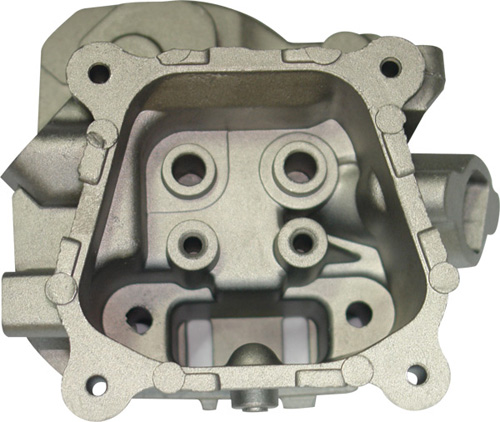

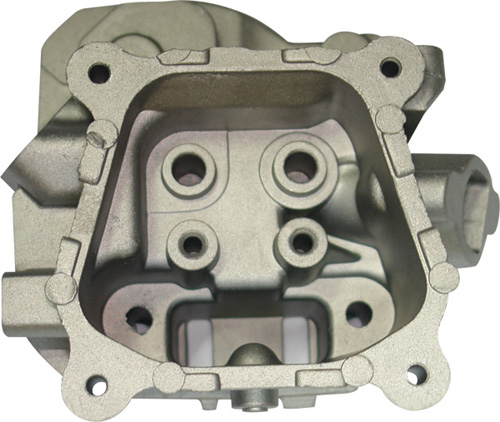

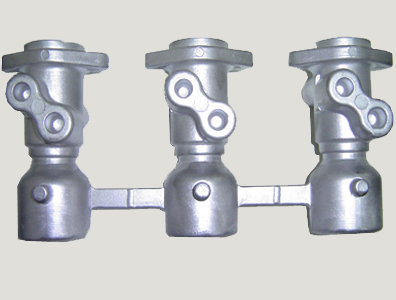

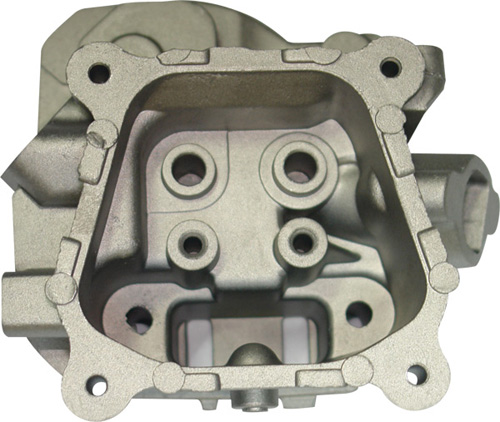

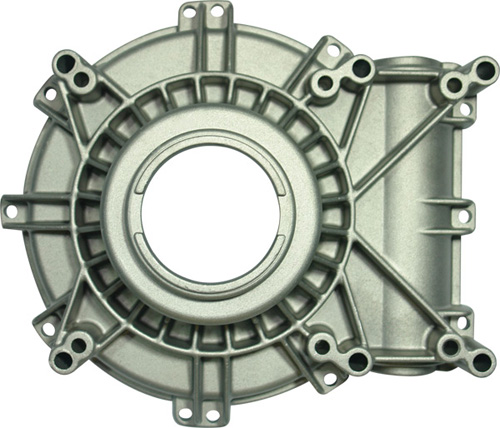

Because magnesium alloys are extremely active, there is often a layer of oxide on the surface. Therefore, the surface treatment of magnesium alloys has certain difficulties. It is necessary to adopt special treatment methods. The appearance treatment of magnesium alloy is mainly to improve the appearance of Magnesium Die Casting Parts and to improve the wear resistance and anti-corrosion functions. Its functions include the following: