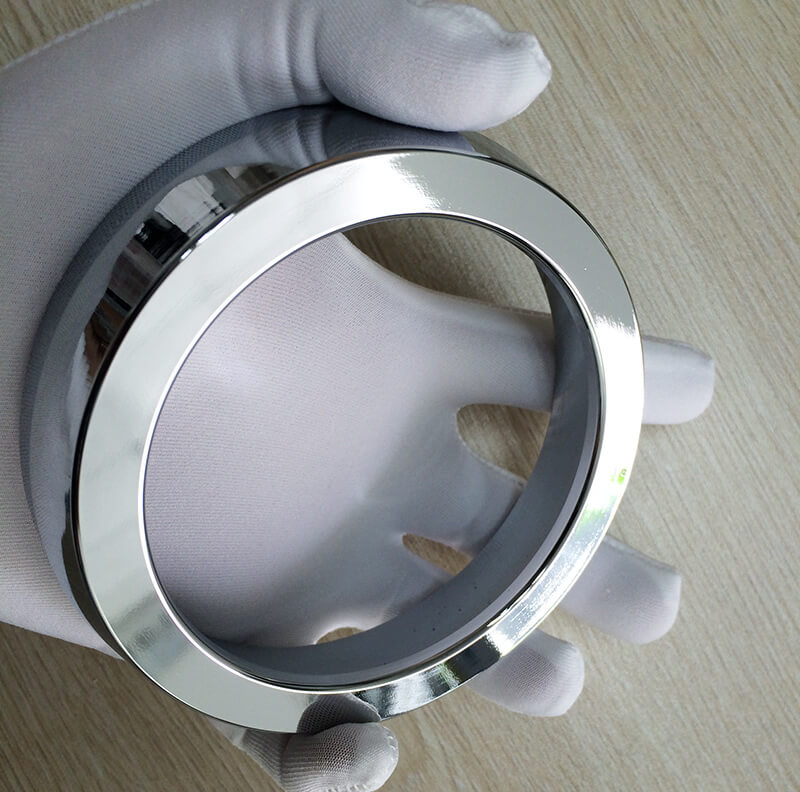

Magnesium alloys is an extremely low density and high strength-to-weight ratio. The magnesium parts combine the advantage of both aluminum and zinc alloy part. The disadvantage of magnesium is that it is easy to creep(cold flow), Because of this, magnesium parts should not be used in very high stress or very high temperature environments.