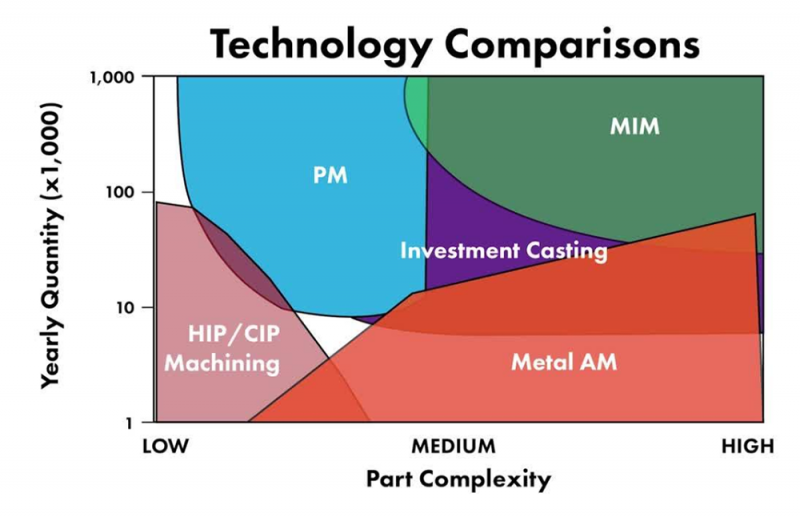

From machining to MIM, metal parts buyers have a wide range of options for addressing their part-production challenges. The key in choosing from among them is to remember that each technology brings something different to the table, and every part has unique requirements.