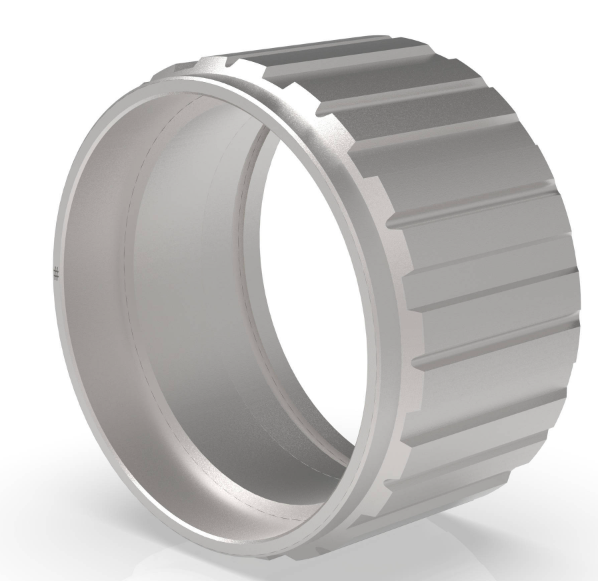

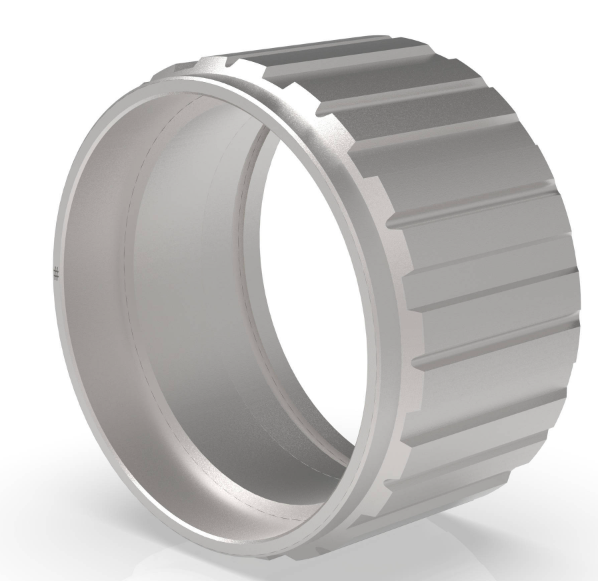

Maintenance and storage of aluminum alloy die casting mold

Release time:2024-03-04

Maintenance and storage of casting-china.com' target='_blank'>aluminum alloy die casting mold

Ustar has a large number of metal die-casting models, good management and storage is essential, die-casting plant for die-casting mold maintenance and storage requirements are as follows:

First, mold maintenance

If the surface of the cavity is ablated or pulled, it should be polished and polished; The crack on the surface of the cavity can be strengthened and polished by tungsten extremelizer. Cracks, pits and scratches can be welded and repaired, and then processed, polished, polished and partially nitrided by a duplicate machine.

2. Mould storage

1 Keep the new mold should have the number, drawing, inspection certificate and die-casting parts qualified for the test mold; There should be a description of the use of the used mold; The repaired mold should be countersigned by the technology and quality department of Nchuang Technology.

2 accounts, cards, things consistent, a model a card. The ledger shall record the storage time, storage place, number, name and quantity of the mold. The card should record the mold number, name, manufacturing time, use time, die casting name, material, sketch, supporting die casting machine, use conditions, maintenance.

3 The mold in storage should be covered with anti-rust oil, and the guide rod holes should be sealed with paper to prevent sand and dust from entering.

4 Mold can not be disassembled storage, so as not to damage the working parts, storage should be classified storage and placed neatly, the bottom is best padded with sleepers.

5 For molds that are not used for a long time, the degree of preservation should be checked frequently.

6 Spare parts of some wearing parts should be put in order to repair the damaged structural parts in time, and the storage amount of spare parts should not be too much, generally 2 to 3 can be.