Which products will use aluminum alloy die casting in the production process

Release time:2023-09-15

With the growth of the market economy and the vigorous development of various industries, the market demand for casting-china.com' target='_blank'>aluminum alloy die casting is also increasing, the application range of aluminum alloy die casting is also more and more wide, and the low pressure injection die casting process has also changed to the use of high pressure casting process. This low-cost, high-efficiency, high-precision batch parts production process has become the mainstream of the market.

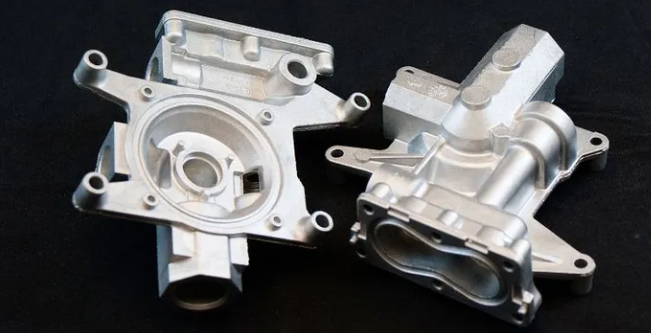

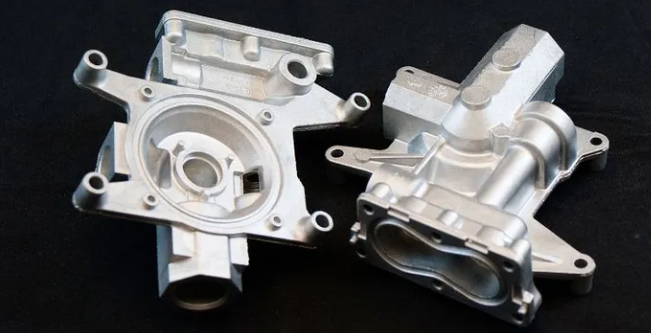

Start with the characteristics of aluminum alloy die casting parts

Aluminum alloy die casting by virtue of the natural characteristics of aluminum, widely popular in the market.

1. Durability: aluminum stability is strong, oxidation resistance, aluminum castings will not rust, corrosion resistance; The surface is sprayed with electrostatic powder, and the various products produced can remain colorless for a long time.

2. Plasticity: The ductility of aluminum is good, and it is easy to design a variety of shapes. It has toughness, can be used repeatedly, and has a wider range of applications.

3. Safety: After a variety of strict tests, to ensure the resistance of aluminum alloy die casting to high temperature, wind and rain, acid and alkali and other factors.

4. Lightweight: Aluminum alloy die-casting parts also have the characteristics of light weight, more convenient installation and maintenance.

Therefore, aluminum alloy die-casting parts are widely used in the automobile industry, gas turbine production and manufacturing, motorcycle production and manufacturing, motor production and manufacturing, gasoline pump production and manufacturing, transmission system machinery and equipment manufacturing, instrumentation, landscape architecture, architectural engineering, architectural decoration design, household appliances, furniture, medical supplies and other industries.

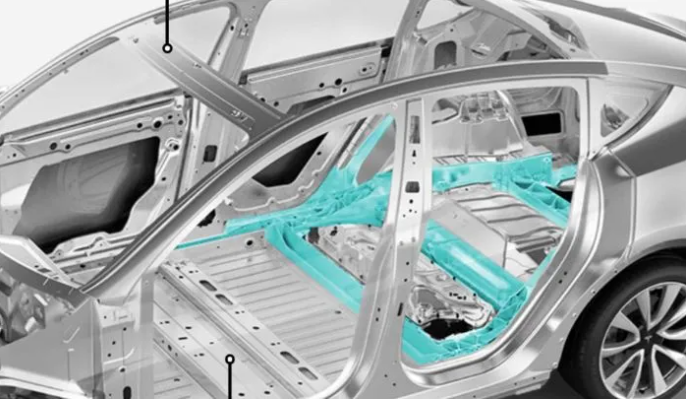

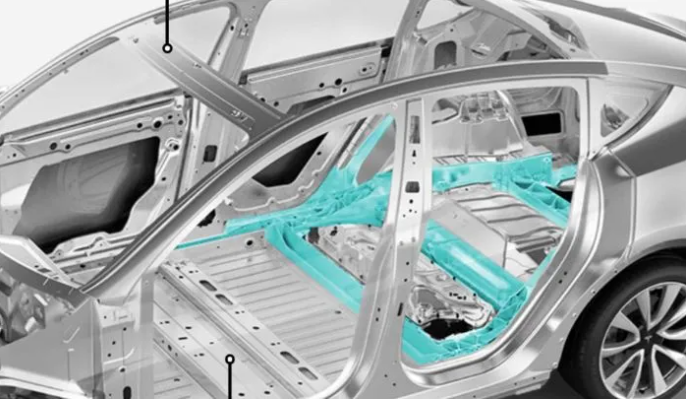

In the automotive industry, aluminum alloy die casting is widely used

The automotive industry is the most widely used aluminum alloy die casting industry, from the body to parts, almost can see the figure of die-cast aluminum alloy, which is due to the excellent corrosion resistance and robustness of aluminum alloy compared with other materials, and its lightweight is also crucial. The use of aluminum alloy die-casting, under the premise of ensuring the safety of drivers and passengers, greatly reduces the weight of the body, reduces fuel consumption, saves energy, environmental protection and reduces production costs. Secondly, die-cast aluminum alloy can produce complex shaped parts at will, which is also an important reason for the extensive use of it in the automotive industry. At present, almost all the car engine cylinder head, transmission housing, clutch housing, water pump housing, carburetor housing, steering housing, etc., are aluminum alloy die-cast parts.

The communication industry is also a key industry in the application of die-cast aluminum alloy accessories

In recent years, with the development of mobile Internet 5G communication industry, the establishment of a large number of communication base stations also requires a large number of aluminum alloy die-casting accessories, aluminum alloy high thermal conductivity is widely used in communication equipment radiator, radiator shell made of aluminum alloy die-casting not only has good heat dissipation, but also can prevent rust and corrosion, for the base station equipment that is almost exposed to outdoor all year round, It's a great choice.

However, due to the fierce competition, many aluminum alloy die-casting procurement enterprises in the communications industry, the payment terms are relatively poor. It seems that the industry opportunity is very good, but to do a good job in the industry of aluminum alloy die-casting supporting supply, it is not so easy.

Furniture die casting, gardening, lighting die casting, more common in life

There are also many products in life that cannot be separated from aluminum alloy die-casting accessories, common household appliances, lamps, furniture, kitchenware, furniture accessories, digital shell, arts and crafts, security product shell, LED lighting (lampshade) and some new energy industries, etc. Some high-quality aluminum alloy die-casting products with high performance, high precision and high toughness are also used in large aircraft, ships and other industries with high requirements.

Common office furniture die casting, airport chair die casting, auditorium chair die casting, etc., are important objects of aluminum alloy die casting.

Many office furniture parts, such as the chair base, handrails, frame structure, etc., the use of aluminum alloy die casting is very common.

In horticulture, many garden supplies are made of aluminum alloy.

In terms of lighting die casting, whether indoor lamps or outdoor lamps, the shell of lamps and lanterns is also particularly common.

Because aluminum alloy die casting is not easy to oxidize, it can maintain its original color for a long time, and it can maintain its original strength and hardness for a long time, so the use of aluminum alloy die casting scenes is much more than what we describe here.