Aluminum casting motor shell production process

Release time:2023-09-25

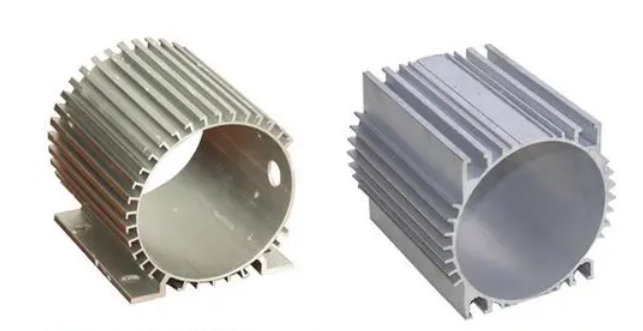

Aluminum casting motor shell production process

The production and processing method of aluminum casting motor housing usually includes the following steps:

Design and mold manufacturing: First of all, according to the design requirements of the motor housing, the three-dimensional design of the housing. Then, according to the design drawings, the mold of the aluminum casting is made. Molds are usually made of metal materials and are used to form the shape of aluminum castings.

Molten aluminum and pouring: the aluminum alloy material is heated to the melting point to obtain liquid aluminum liquid. The molten aluminum is then poured into a pre-prepared mold. During the pouring process, it is necessary to pay attention to controlling the temperature and pouring speed of the liquid aluminum to ensure that the liquid aluminum is fully filled with the mold and avoid the generation of bubbles and defects.

Cooling and curing: After the aluminum liquid is fully filled with the mold, it is necessary to wait for a period of time for the aluminum liquid to cool and cure. The cooling time depends on the temperature of the liquid aluminum and the size of the housing. Natural cooling or auxiliary cooling, such as water cooling or wind cooling, is usually used to speed up cooling.

Mold opening and removal of aluminum castings: After cooling and curing, open the mold and remove the aluminum castings that have been formed. During this process, care is required to avoid damaging the aluminum castings.

Dressing and machining: The removed aluminum castings usually have some burrs, pores or other defects that need to be trimmed and processed. This includes the removal of burrs, sand holes and poor surfaces, as well as the necessary machining processes such as drilling, milling, etc., to meet the accuracy and functional requirements of the housing.

Surface treatment and painting: Finally, the surface treatment of aluminum castings, such as polishing, sandblasting, etc., to improve the appearance quality. Then, paint is applied as needed to increase the corrosion resistance and aesthetics of the casing.

The above is the basic step of production and processing of aluminum casting motor housing. Specific processing methods may vary depending on product design and manufacturing requirements, but the overall process is broadly similar.