Influence of die casting die design on die life

Release time:2023-09-23

Influence of die casting die design on die life

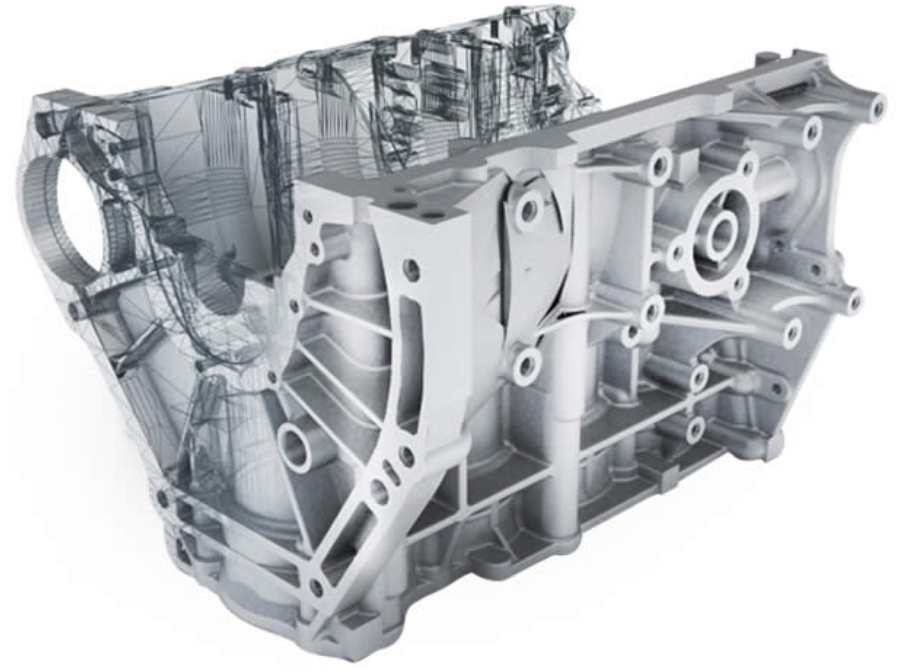

Die casting die design is another important factor affecting die casting die life, die design is good or bad, directly affect die casting die life. Therefore, in the die casting mold design must be based on the characteristics of the casting, fully consider the factors affecting the life of the mold, reasonable design of the mold structure, in the early stage for the casting design affecting the life of the mold timely improvement suggestions, or take reasonable measures to solve.

1, mold strength is enough

Whether the strength of the mold is enough is an important factor affecting the life of the mold, for this point, most enterprises in China, including die-casting enterprises in the purchase of molds, generally pay special attention to the price of the mold, and even think that as long as the die-casting qualified products are on the line, for the size of the mold, whether the strength of the mold is enough has not attracted enough attention. At the same time, many die casting mold manufacturing enterprises in order to obtain orders, often the mold price is low, and in the mold production can be saved to reduce costs. If the strength of the mold is not enough, it will not only affect the reliability of the mold, but also affect the life of the mold. In fact, from the point of view of die casting production, such molds are not economical. If the strength of the die casting mold is not enough and the rigidity is poor, the mold will crack prematurely under constant impact and pressure. And because the sealing aluminum surface is too small, it will cause the mold to channeling aluminum, and it will not clean and press the mold in time, resulting in mold damage. Therefore, the mold strength must be fully considered in the mold design to ensure the life of the mold.

Hardness is the main technical index of die steel, die under the action of high stress to maintain its shape and size unchanged, must have a high enough hardness. The general hardness of cold working die steel at room temperature is maintained at about HRC60, and hot working die steel is generally required to be kept in the range of HRC40 ~ 55 according to its working conditions. For the same steel, in a certain range of hardness values, hardness and deformation resistance is proportional; However, the plastic deformation resistance of steel with the same hardness value and different composition and structure may be significantly different.

Hot working molds that work at high temperatures require to maintain the stability of their organization and performance, so as to maintain a high enough hardness, which is called red hardness. Carbon tool steel, low alloy tool steel can usually maintain this performance in the temperature range of 180 ~ 250 ° C, chromium molybdenum hot work die steel generally in the temperature range of 550 ~ 600 ° C to maintain this performance. The red hardness of steel mainly depends on the chemical composition of steel and heat treatment process.

c Compressive yield strength and compressive bending strength The mold is often subjected to high strength pressure and bending during use, so it is required that the mold material should have a certain compressive strength and bending strength. In many cases, the conditions of the compression test and the bending test are close to the actual working conditions of the die (for example, the measured compressive yield strength of the die steel is more consistent with the deformation resistance shown by the punch when working). Another advantage of the bending test is that the absolute value of the strain variable is large, which can sensitively reflect the difference of deformation resistance between different steel grades and under different heat treatment and microstructure.

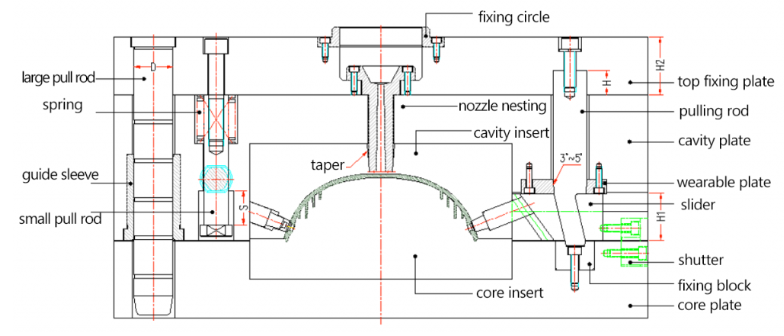

2, mold gate speed is appropriate, should be as low as possible

The design of the gate in the die casting mold is not only an important factor affecting the quality of the casting, but also directly affects the life of the die casting mold, so it must be attached great importance in the design of the die casting mold. The faster the speed of the gate in the die casting mold, the greater the impact on the mold cavity, the greater the instant temperature rise of the mold cavity, the more prone the mold surface cracking or cracking. The gate in the die casting mold is generally 30-70 meters/second, and in the case of ensuring product quality, it is as low as possible, so that the impact on the mold can be reduced, thereby extending the life of the mold. Under certain injection conditions, when the inner gate area is too large, the filling speed will be too low, the metal will be premature solidification, and even lead to insufficient filling. However, too small inner gate area will aggravate the injection, increase the heat loss, generate eddy currents and involve too much gas, aggravate the erosion of the mold, and lead to the early scrapping of the mold.

A. The size of the cross-sectional area of the inner gate is often determined by experience in the process of design drawing. The cross-sectional area of the inner gate calculated solely based on the empirical formula breaks the close relationship between the cross-sectional area of the inner gate and the filling speed and filling time, and there is a risk that the cross-sectional area of the inner gate cannot be effectively matched with the filling speed and filling time. It is not clear to the designer how far the design results can be modified.

b. There is a wide difference in the cross-sectional area of the inner gate. In production practice, it is not uncommon for the cross-sectional area of the gate in the mold to not match the die casting. When the mismatch is small, the performance is not obvious. When the gap is large, it will be obvious that the die casting can not be formed, the scrap rate is high, and the quality is unstable.

c. In the production process, there will be high requirements for process parameters, and slight fluctuations in the process will cause a variety of defects on the surface of the die-casting parts. If such a mold is put into a die-casting machine with higher performance, it is possible to smoothly produce qualified die-casting parts, but it is difficult to produce normally on the existing die-casting machine.

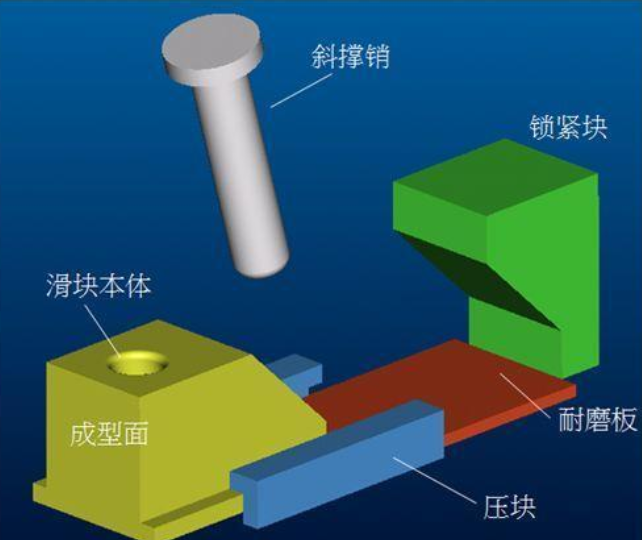

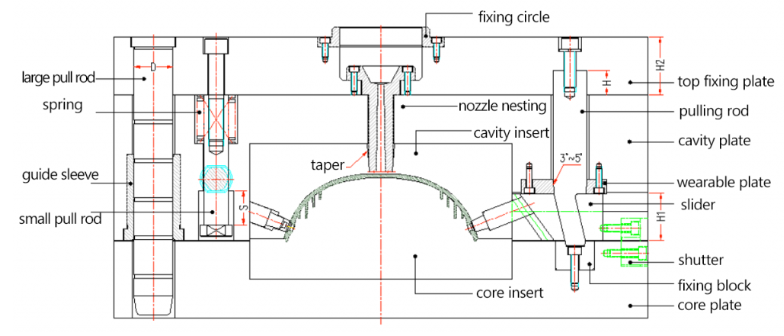

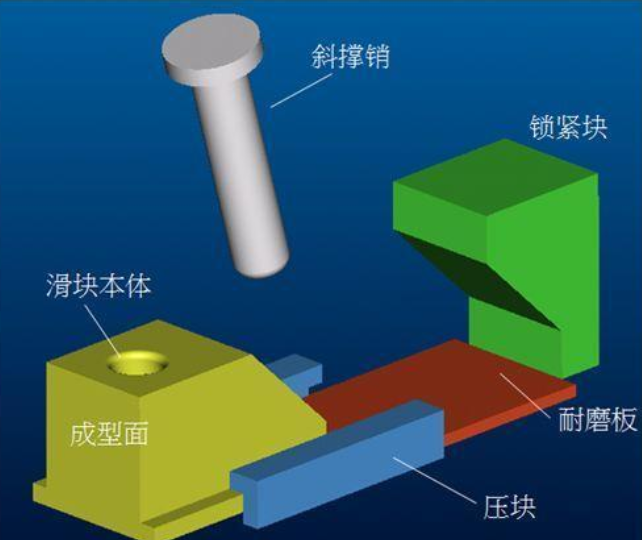

3, mold slider lock block strength is enough

Because die casting is high-speed, high pressure, die casting die slider by the impact force is very large, die casting pressure is generally selected in 400-900 kg/square centimeter, to the slider projection 100×100mm, for example, the force is 40 tons to 90 tons, therefore, many die casting mold companies in the design of the mold generally in order to save materials, mold design is small, The lock block is not large enough, the strength is not enough, resulting in the slide block cannot be locked. Not only will it affect the quality of the casting, at the same time, it is easy to cause channeling aluminum, resulting in the slide block stuck, causing deformation or cracking of the mold lock part, thus damaging the mold and affecting the life of the mold. Therefore, when designing the mold, it is necessary to ensure that the strength of the locking block of the mold slider is enough to ensure the reliability of the mold and extend the life of the mold.

4, mold cavity sealing aluminum surface is enough

Because die casting is high temperature, high speed, high pressure, die casting mold by aluminum is often occurred, the reason is, in addition to the improper choice of die casting parameters, the injection speed is too fast, the pressure is too large, the clamping force is not enough, the mold design is unreasonable, the aluminum surface is not enough is also one of the important reasons. If the mold channeling aluminum, on the one hand directly affects the internal quality of the casting, on the other hand, because in the die casting process, it is not timely or difficult to clean, it will crush the mold, causing the mold parting surface to collapse. More seriously, in the mold with the slider structure, if the aluminum is channeled into the gap between the slider, the slider or the slider seat will be damaged due to the very large clamping force when the mold is closed, and even the mold frame will be squeezed. This phenomenon often occurs in die casting enterprises. The reason is mainly caused by die casting enterprises or mold manufacturing enterprises in order to save costs, making the mold too small, and the sealing aluminum surface is not large enough. There is a phenomenon, it is worth our reflection, the Japanese are very economical, but the die casting mold made by the Japanese is basically larger than the mold made by most manufacturers in China, why? Because if the die casting mold only considers the cost, and ignores the most critical characteristics of the mold, namely: reliability, yield, production efficiency, and life, it will be more than worth the loss. This is also the gap between China's die casting mold and foreign advanced countries. This concept is not only die casting mold manufacturing enterprises need to change, but also die casting mold use enterprises should be reversed. Therefore, when designing the mold, great attention should be paid to the sealing aluminum surface, especially the sealing aluminum surface in the slider part, which must be enough to ensure that no aluminum is channeled, thereby extending the life of the mold.

5, mold cooling (heating) design is reasonable, mold temperature field is reasonable

The design of mold cooling water is a crucial link in the design of die casting mold, and most die casting mold manufacturers in China often attach great importance to the pouring system.

The temperature of the mold will be too high or even reach the bottom of the normal production; The mold may also be scrapped due to excessive temperature resulting in mold deformation; The mold life will be greatly reduced; There is also the failure of high temperature oxidation of the mold surface.

When many manufacturers use mold flow analysis software, they often study the filling part a lot, but not much research on the change of mold temperature field. In fact, in die casting production, mold cooling and mold temperature field changes are crucial to production efficiency, casting quality and mold life. Conditions can use die-casting special die temperature machine, help to improve production efficiency, improve casting quality, but also can extend the life of the mold. During the use of aluminum alloy die casting mold, the liquid aluminum alloy fills the mold cavity instantaneously, making the mold surface withstand high temperature and the surface temperature rises. The cooling forming of die casting aluminum alloy products is to transfer the heat emitted by the aluminum alloy solidification process to the mold as a thermal conductor. Because the shape of the die casting product is irregular, that is, the thickness of the product is not uniform, then the heat emitted by the casting product during the solidification process is different. In the process of mold design, it is necessary to effectively design the internal cooling water channel distribution of the mold to minimize the surface temperature difference of the mold. In this way, the difference in mold surface temperature can be reduced to control the deformation of die casting products, reduce the occurrence of shrinkage holes, and ensure the production rate and production rhythm. The control of mold temperature field needs to be considered in the early stage of mold design. That is to say, it is necessary to set the production rate and production tempo (such as: 60 products/hour) to understand the thermal power emitted by the mold during the production process. After understanding the thermal power emitted by different thickness parts of the mold during production, the diameter of the cooling water channel, the distance from the surface, and the flow rate of the cooling water are calculated, so as to control the surface temperature of the mold at 240 degrees. At present, the common problem is that the establishment of the temperature field is not based on calculation, but according to experience, roughly estimate the distance from the surface of the cooling water channel, and the aperture of the cooling water channel. As a result, the mold surface temperature is difficult to reach uniformity. When the mold is overheated, a large amount of release agent is sprayed to cool the mold. The result is that after the mold is used for a short period of time, such as more than 3000 molds, thermal fatigue cracks appear on the surface of the mold. In the subsequent production process, due to the continuous severe cold/hot cycle of the mold, the early failure of the mold did not reach the predetermined life requirements of 80,000-100,000 mold times. Thus greatly reducing the life of the mold. Therefore, optimizing mold cooling (heating) design is the key to improve mold yield and production efficiency, and it is also a very important way to extend mold life.

6. Whether the vulnerable parts are inlaid

In order to extend the life of the mold, in the mold design, the complex cavity can be processed in blocks to simplify the process, and the parts prone to mold cracking and mold damage can be inserted, on the one hand, it is easy to maintain and replace to reduce the cost of mold manufacturing; On the other hand, the Mosaic joint can block the extension of the crack. It also avoids local cracking spreading to other parts, thereby extending the life of the mold.

7. Reduce the sharp Angle of stress concentration

The sharp corners are prone to stress concentration, therefore, for die casting parts, the sharp corners of the corners, both from the casting process, casting quality, and die casting die life are very important. Therefore, when discussing the problem with the casting designer in the early stage, it is very important to pay great attention to the Angle of the casting and increase it as much as possible.

8. Adopt advanced technology

In order to extend the life of the mold, many scientific and technological personnel, including China, are actively exploring some new technologies, such as new surface nitriding technology, titanium plating, surface micro-grid life extension technology and so on. Therefore, as a die casting mold manufacturing enterprise, as a die casting mold designer, actively explore new technologies, timely track advanced technologies, timely use of new technologies to improve the life of the mold, is also an effective way to improve the level of die casting molds and improve the technical level of enterprises. Huiwang Company has made exploration in this aspect, applied many new technologies, and achieved good results.