Al die casting wall thickness is vital for die casting half .wall thickness is that the distance between 2 parallel or nearly parallel surfaces. Ideally, the Same thickness is healthier for create the glorious metal die casting .and The typical wall thickness for a forged style varies from zero.040 in. (1.016) to 0.2 in. (5.08), depending on the construction, application, size, etc. except for your ideal style, syx assist you started extraordinary thickness in line with your die-forged product. I’ll tell you all this during this diary post .how to create over eight metric linear unit thickness for your die-forged part and the way you must select appropriate thickness

the customary wall thickness of die-forged Al

Keep the vary of thickness at intervals 2X of the thinnest wall, and keep the wall as skinny as potential to fulfill the castings practical necessities

what number most wall thickness is created by a metal die casting

As the thickness of a die casting half will increase ,strength decreases, void, and pits, porosity comes within the inner.

if you merely wish a lot of serious for die casting half, we propose to feature some ribs, pls see die casting heatsink

The syx will meet the need for thick. we tend to create twenty metric linear unit thickness for our client by massive die casting machine and glorious technology.

what is best thickness for die casting half, why it’s vital for die casting product

Thin-walled die castings have higher strength and higher compactness than thick-walled die castings.It has been well-tried that a pair of.5-4mm is appropriate for the look, and therefore the die casting method isn’t appropriate for elements whose wall thickness exceeds eight metric linear unit

|

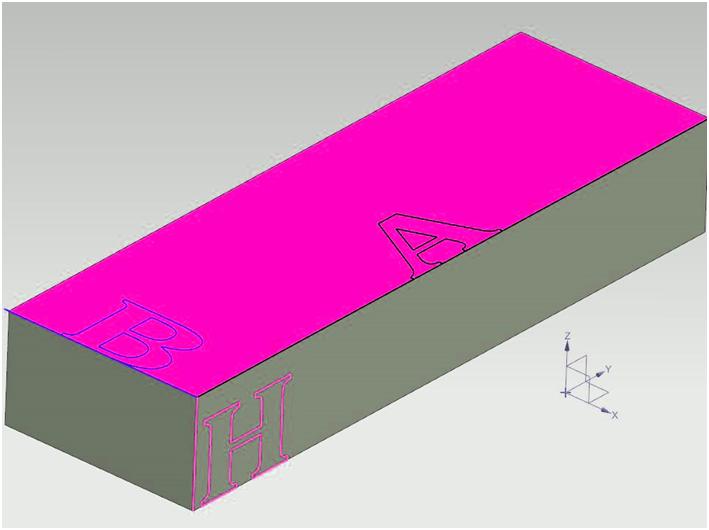

The red area at the wall thickness

|

Zinc casting |

|

||

| Wall Thickness H(MM) | ||||

| min | normal | min | normal | |

| ≤25 | 0.5 | 1.5 | 0.8 | 2 |

| >25-100 | 1 | 1.8 | 1.2 | 2.5 |

| >100-500 | 1.5 | 2.2 | 1.8 | 3 |

| >500 | 2 | 2.5 | 2.5 | 4 |