In manufacturing, quality control is a process that ensures customers receive products free from defects and meet their needs. When done the wrong way, it can put consumers at risk. For example, the recent defect found in Takata airbags resulted in the biggest automotive recall in history. The recall includes almost 69 million airbag inflators and may cost billions of dollars. The recall will last until the end of 2019 and take until 2020 to resolve.

Major recalls like these can be prevented through effective quality control in manufacturing. Some common tools used to support quality control include:

Statistical process control (SPC) monitors and controls quality by tracking production metrics. It helps quality managers identify and solve problems before products leave the facility.

Six Sigma uses five key principles to ensure products meet customers’ needs and have zero defects.

When supported by lean tools like Total Productive Maintenance (TPM), 5S, and Kaizen, most if not all defects can be eliminated.

Benefits of Using Quality Control in Manufacturing

Customers expect and demand high-quality products. When customers receive quality products you will:

Increase customer loyalty

Gain repeat business

Gain new customers from referrals

Maintain or improve your position in the market

Improve safety

Reduce liability risks

Contribute to overall positive branding of your product

Manufacturers with quality control procedures in place are far less likely to face product recalls or place customers at risk from poorly made products. The cost associated with these recalls can be steep. Testament to this is the Takata recall, which is estimated to cost the company between $7 and $24 billion.

Discover how you can avoid costly recalls and support your quality control system with TPM. Graphic Products’ Best Practice Guide to Total Productive Maintenance (TPM) will help you on the road to total quality. Improve quality, eliminate defects, and increase your profits.

Incorrect Implementation of Quality Control in Manufacturing

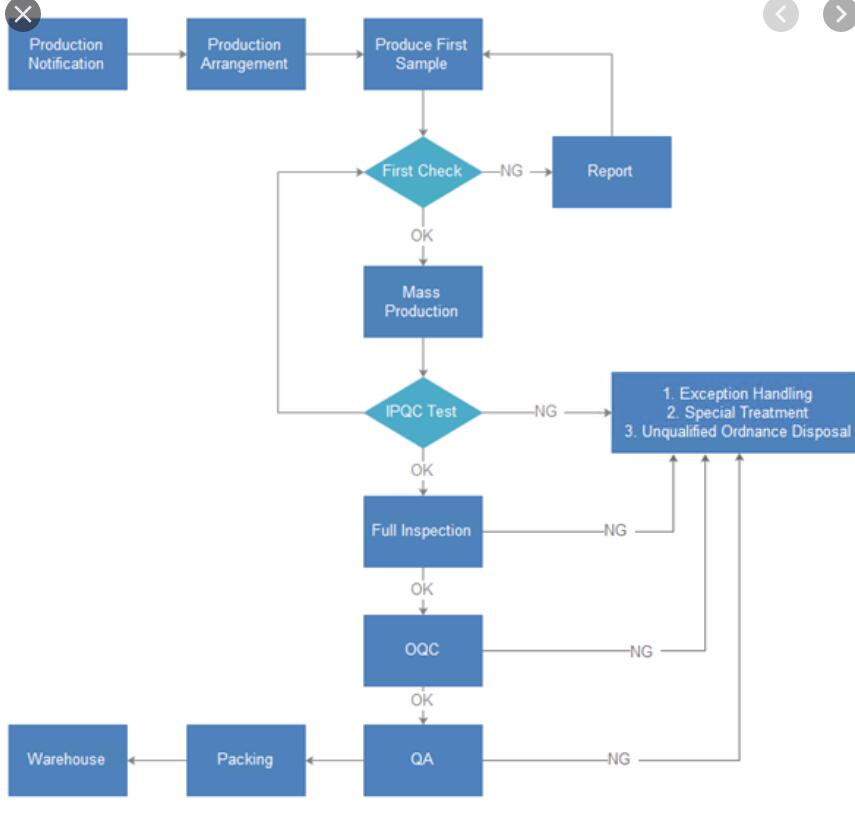

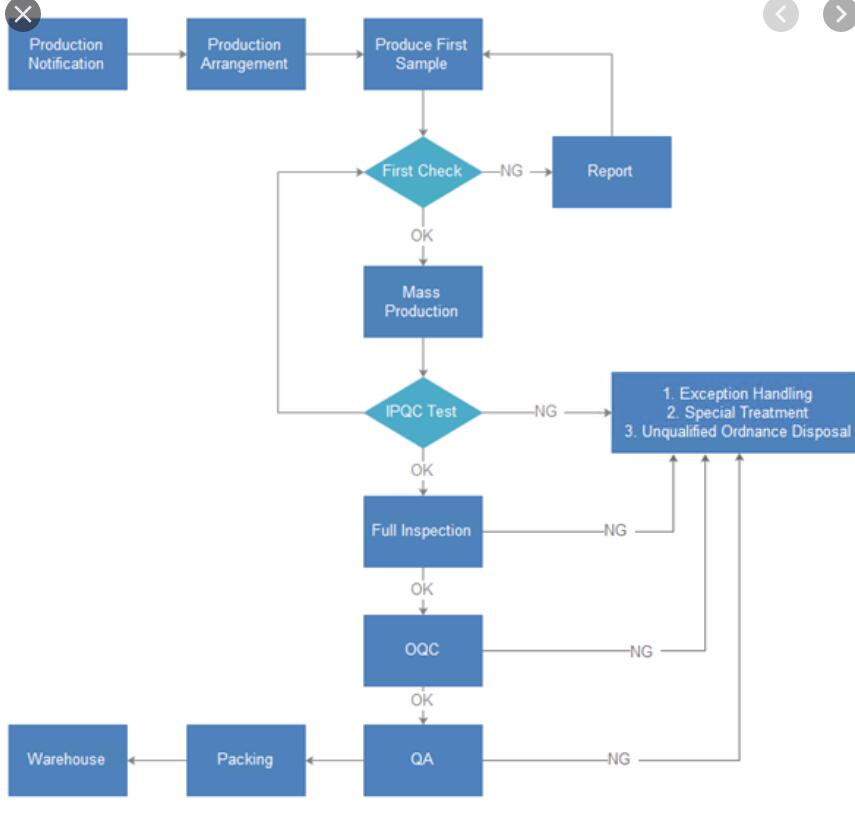

Quality control in manufacturing can be a little tricky. Often, it is done at the end of the production process, only catching defects after the fact.

Effective quality control is more involved and should include two levels:

Operators monitor the manufacturing process and ensure that there is little variation.

Engineers routinely monitor the product design for issues. When a problem is found, it is immediately fixed.

By monitoring products at the end of production as well as reviewing the products’ design, companies can solve problems more efficiently, saving time and money.

Kaizen Best Practices Guide

A free guide to reducing costs and increasing productivity.

Quality Assurance with Quality Control

Quality assurance streamlines production and helps to ensure that the final products meet the company’s quality criteria. It ensures that the processes used to design, test, and produce products will be done correctly.

In manufacturing, quality assurance approaches, like ISO 9001, help manage and improve many processes, including:

Acquiring raw materials

Purchasing third-party components and sub-assemblies

Designing and using inspection procedures

Complying with production processes

Responding to defects

For every business, quality assurance is different. However, ISO 9001 works for businesses both large and small and can be adapted for most any need. It provides the means for creating a lasting quality assurance program, ensuring that everything, from raw materials to inspection procedures are of the highest quality. Issues and defects from poor quality materials or third-party components are all but eliminated.

Quality Control, QA and Lean Manufacturing

Lean manufacturing tools can bolster your company’s quality program. Lean revolves around improving quality and safety while increasing efficiency and profits. Some powerful lean manufacturing tools that can bolster your quality system include:

TPM improves product quality by eliminating downtime, defects, and accidents. TPM accomplishes this through comprehensive maintenance programs and operator training.

Kaizen helps eliminate problems at their source by empowering workers to find and solve problems on a daily basis.

5S helps organize and standardize the workplace. Take control with the 5S System Best Practice Guide, by Graphic Products. Improve procedures and eliminate errors in your facility.

While every facility has different needs and may require a different lean tool, using lean to support quality control is essential. Procedures will be simplified, and the number of errors will be reduced.

Learn more about Kaizen and how it can help improve quality with this helpful video.

How to Implement Quality Control in Manufacturing

To implement an effective quality control program, first create and document your approach to quality control. This includes:

Defining the quality standards for each product

Selecting the quality control method

Defining the number of products/batch that will be tested

Creating and training employees for quality control

Creating a communication system for reporting defects or potential issues.

Next, you will need to create procedures for handling defects. Consider the following:

Will batches be rejected if defected items are found?

Will there be further testing and potential repair work involved?

Will production be halted to ensure that there are no more defective products created?

How will new product versions be handled?

Finally, use a method like 5-Whys to identify the root cause of the defect, make any needed changes, and ensure your products are defect free.