Everyone knows that in the field of die casting mold processing, there are many factors that affect the price, even if the prices of different manufacturers of the same set of die casting molds are different. So why are these differences? What are the factors that determine the processing price of die casting molds?

Factors affecting the price of die casting mold processing:

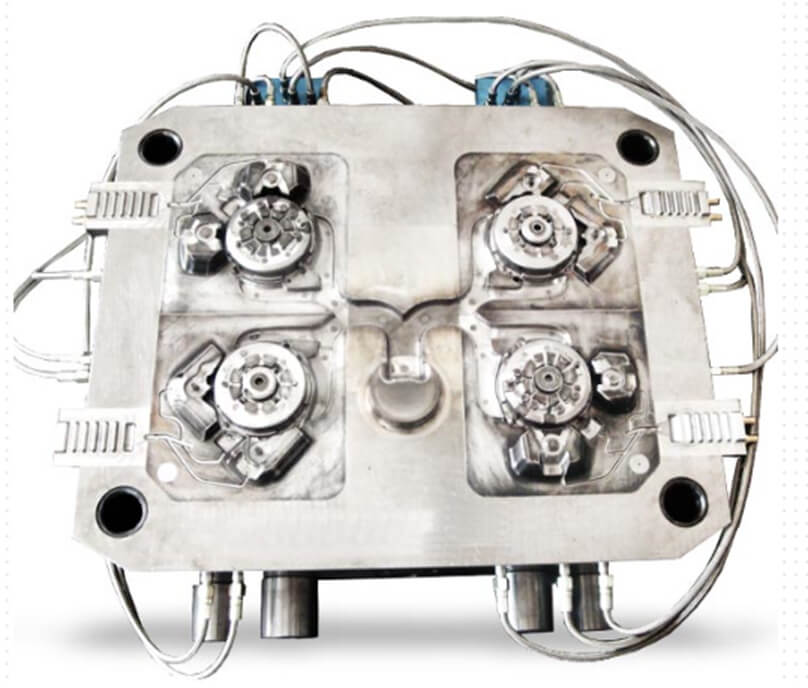

Reason 1: In the face of die-casting molds with different structures, the manufacturing process is different. Some can be solved by mold design, and some can be processed by subsequent post-processing. In this case, the former is usually chosen.

Reason two: Different die-casting mold processing equipment will also affect the price. Take common electric discharge machining as an example. Some are processed by ordinary spark machines, and some products require mirror-sparking machining. Then the price of these two types It is completely different. The price of mirror spark machines is often about twice as high as ordinary.

Reason three: The material selection of the die casting mold also has a great impact on the price. Some die castings have special requirements, so it is also important for the choice of mold steel. Although they can be made, some differences in the price of different material selection can reach 20% to 30%.

Reason 4: Different die-casting equipment also has an impact on the price. For the same set of die-casting molds, the price of the die-casting equipment of different tonnage is also changed. For example, it can be produced with a 88-ton die-casting machine, but due to various special circumstances, a 168-ton die-casting molding equipment is selected, then the price of the die-casting mold processing brings a difference, because the output and labor cost of the two equipment are different.