The oldest known casting process, sand casting can be traced back to earlier than 1000 B.C. Process controls, material options, tolerance capabilities, the ability to produce elaborate parts, broad size ranges – those have all come a very long way, of course. But the metals fundamentals are relatively unchanged. Create a cavity in the shape of the part you want, and pour molten metal into it.

The result of centuries of development is that sand casting is the most versatile, and probably the most widely used, metal casting method.

Design requirements (including shaping and dimensional needs), piece and tooling cost, quantity needed, and even feasibility to manufacture dictate which metalworking processes (including which casting processes) are most suitable when choosing how to manufacture a product.

The sand casting process employs techniques that produce shaped parts of nearly any design, including very large parts and those with internal passageways. There may be more optimal casting or metalworking processes for any specific product, based on needed tolerances, design intricacy, volume, tooling availability, or lead time, but it is likely that a casting in the needed configuration could be made using the sand process. That is a decision left to the design engineer.

The process is referred to as sand casting because the mold that contains the cavity into which metal is poured is made of compressed or compacted sand. The sand contains some other material that encourages it to hold its shape.

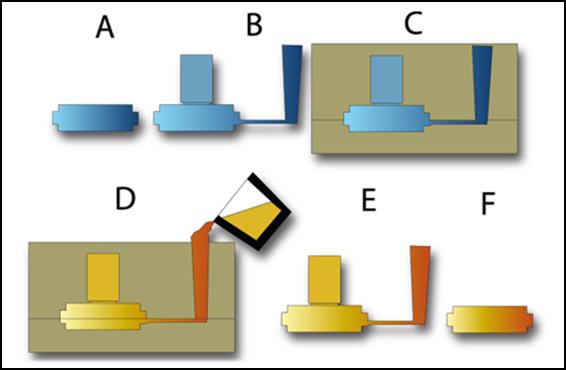

The process utilizes a reusable pattern with the same details as the desired finished part. There is an allowance for thermal contraction or shrink.

The pattern produced in step “A” also includes the metal pathways that will feed the desired cast product design with appropriate gating and risers. This drives the inevitable thermal contraction to acceptable areas (someplace other than the actual desired finished product), and manages metal flow and needed gas venting.

Patterns are made of many different materials such as wood, metal, synthetics, expendable polystyrene (EPS), and others depending on needed volume and tolerance.

A refractory material which is stable at high temperature (sand, in our example) is formed around the pattern. The material must be strong enough to hold the weight of the molten metal during casting and resistant to reaction with the metal, yet brittle enough to be readily broken away from the solidified metal after the casting cools.

The sand casting process is a versatile and well understood process. Process refinements over time have helped make sand casting the process of choice for applications in many, many industrial markets.

As with most materials and design decisions, a discussion with a metals expert can help drive the best metals decision. For new designs, that is a conversation that best happens as early as possible to optimize manufacturability. But even applications that have used metal components the same way for a long time can be evaluated to provide higher performance or a more cost effective conversion to a different process like sand casting.